Information about Carpet Dusting (Rug Dust beater) Machine

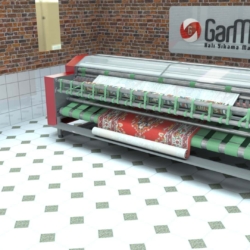

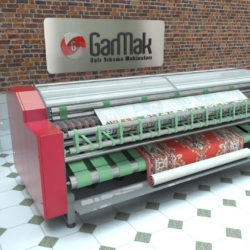

This product is an industrial carpet dusting and whisking/beating machine that quickly removes and vacuums solid carpet dirt such as yarn breaks, house mites, unwanted dust and foreign materials in the pile gaps before carpet washing.

In very dirty carpets, you can speed up the washing process over 50% and save on consumables. The carpet is fed to the machine from its reverse surface and vibrated at 1200 strokes per minute from its back surface and 600 strokes per minute from its front surface. The dust extraction unit, which is supplied with the machine and has high suction power, transfers the dust removed by the stainless beater to the dust bag thanks to the strong air flow.

At the end of the process, the carpet surface is made ready for washing and provides a comfortable wash. Flying dust is trapped in the dust cabinet and vacuumed.

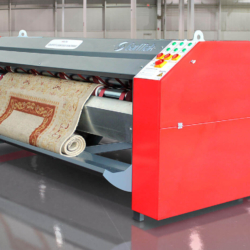

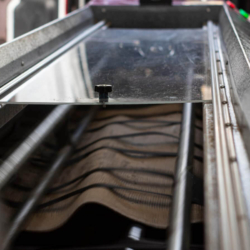

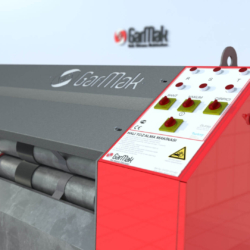

Carpet Dusting (Rug Dust beater) Machine Photos

New Carpet Dust Beater Technical Specifications

Carpet Dust Beater Technical Specifications

| ÜRÜN KODU | D4025 | D4030 | D4035 | D5042 |

|---|---|---|---|---|

| Bant Genişliği | 250 cm | 300 cm | 350 cm | 420 cm |

| Bant Boyu | 150 cm | 150 cm | 150 cm | 150 cm |

| Toz Alma Hızı | 3 m/min | 3 m/min | 3 m/min | 3 m/min |

| Çırpıcı Sayısı | 3x3 | 3x3 | 3x3 | 3x3 |

| Çırpıcı Hızı | 1800 hit/dk | 1800 hit/dk | 1800 hit/dk | 1800 hit/dk |

| Malzeme | Çelik | Çelik | Çelik | Çelik |

| Elektrik Tüketimi | 4 kw/sa | 4 kw/sa | 5 kw/sa | 6 kw/sa |

| Kontrol Paneli | Buton Panel | Buton Panel | Buton Panel | Buton Panel |

| Vakum Debisi | 3000 m³ | 3000 m³ | 4000 m³ | 4000 m³ |

| Rulo Ön Süpürücü | Opsiyonel | Opsiyonel | Opsiyonel | Opsiyonel |

| Otomatik Sarma | Opsiyonel | Opsiyonel | Opsiyonel | Opsiyonel |

| Genişlik | 310 cm | 360 cm | 410 cm | 480 cm |

| Derinlik | 200 cm | 200 cm | 200 cm | 200 cm |

| Yükseklik | 120 cm | 120 cm | 120 cm | 120 cm |

| Ağırlık | 1000 kg | 1200 kg | 1400 kg | 1650 kg |

| Garanti Süresi | 1 Yıl | 1 Yıl | 1 Yıl | 1 Yıl |

| *İsteğe bağlı olarak 60 Hz üretilebilir. - Özel ölçülerde üretim yapılmaktadır. |

||||

Carpet Dusting (Rug Dust beater) Machine Usage Information

- Carpet Dusting Machines work with conveyor band system.

- Carpets, which are given upside down from the front of the dusting machine, are undulated, vibrated, and vacuumed then comes out from the back.

- Its solid chassis and durable band are produced with the strength suitable for the long working tempo of carpet washing factories.

- The button panel, which is very easy to use, does not tire you.

- You can operate the machine with only one employee.

- With this product, you can easily beat 2000 m² of carpet as a result of 8 hours of continuous work per day.

Carpet Dusting (Rug Dust beater) Machine Working System

Considerations

After the entire mechanical and electrical system of the machine is installed (in line with the training to be given), the personnel at the front of the machine:

- programs the machine and place the carpet flat on the band after classifying the carpets and making a preliminary check,

- ensures the regular operation of the machine,

- sets the speed of the band.

- prevents old carpets, which are likely to be torn, from entering the machine with Pre-control.

- helps to wrap the carpet neatly at the back of the machine.

- takes the carpet that has finished its dust beating process to the washing.

While the machine is in operation, the relevant personnel work in accordance with those warnings on the machine:

- "Do not lean on the band!"

- "Do not put your hand between the rollers!"

- "Do not touch!"

- "Attention electrical panel!"

While the machine is in operation ;

- between the band and the rollers,

- nothing other than carpet should be inserted between the beaters.